Know-How

Thread machining with Tauro / Taurox

Based on a counter-balance system, the spindle is free floating. This avoids any axial force to the thread tapping tool and workpiece. With its pitch the tool pulls itself into the workpiece. There is no need to enter the pitch of the tap, since the depth is controlled by a measurement system at all times. The tool always finds an existing thread again, without risk of damaging the same, what makes remachining very easy.

The simple operation

Clearly presented menu-driven operation allows the user to simply input the working parameters by a 4.3“ TFT LCD display with a rotary encoder and push buttons i.e. torque, depth, speed, thread forming, threading a blind hole, etc. The tool is held by a quick change system. The spindle operates from preset parameters to a precise depth and sequence.

The intelligent control unit

The high capacity processors of each single module are networking together. One processor controls the depth while another processor is able to monitor the drive and the torque. Another operates the display and controls the operation. Based to the fact that the drive has its own processor, the control is very fast. It measures the torque constantly and in case of exceeding the set torque it stops the drive before the tool is broken or the workpiece is damaged.

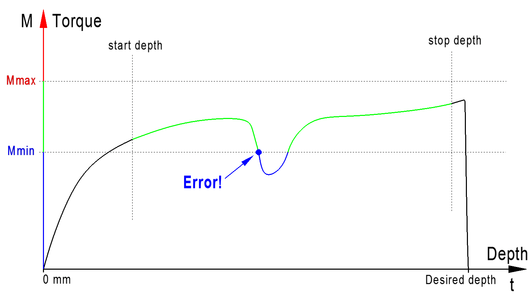

The quality evaluation

The intelligent control unit assures secure processing and quality evaluation. Parameter monitoring happens during operation. The quality evaluation immediately reports the results on the display, like error-free machining, monitoring of operation, excessive torque, tool wear, or pilot hole too large or small.

Dynamic drive

The synchronous servo motor of the Tauro threading machine reaches very high dynamics due to complex control engineering and at the same time an extremely smooth running performance at low and high speeds. Hence even the use of carbide tools is possible.

Detection of cavities

(air pockets and blowholes)

within castings