Process and quality monitoring

The process monitoring happens during the machining

The system

Due to the integrated measuring and evaluation system the process parameters are analyzed during the machining, what gives the possibility to automatically intervene in the process before the part or tool gets damaged.

The process optimization

Cutting speed and parameter optimization

Cutting oil and tool optimization

Tool life optimization

Cycle time optimization

Process analysis

Profits

No additional monitoring system necessary

Detection of errors and deficiencies

Higher productivity

Shorter cycle times

Reduction of material rejects

Tool protection

Lower tool wear

Process evaluation

Quality assurance

Reduction of costs

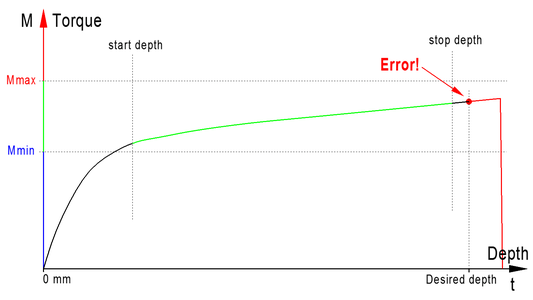

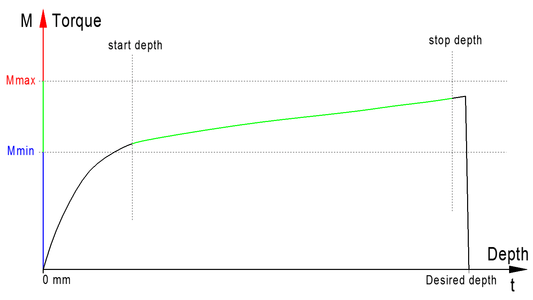

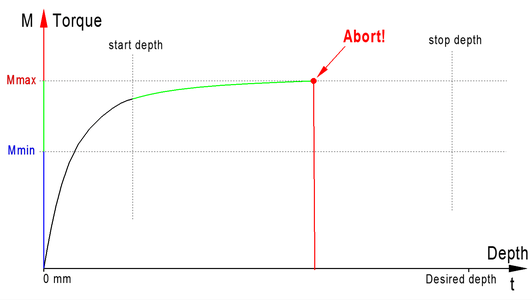

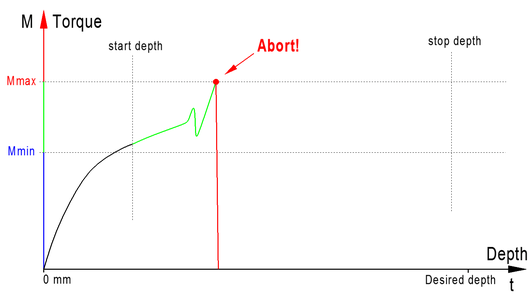

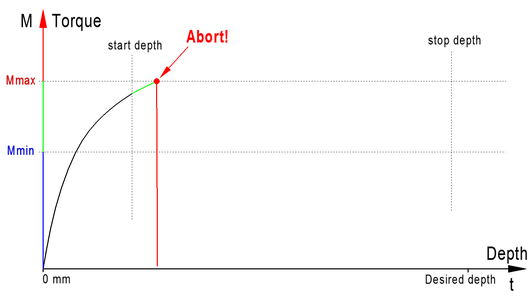

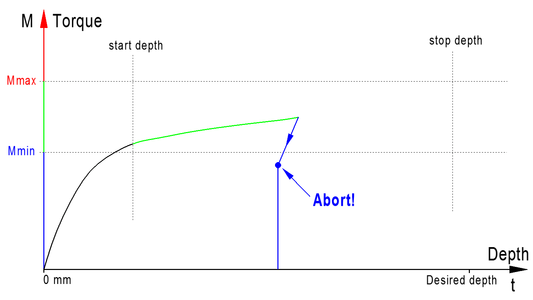

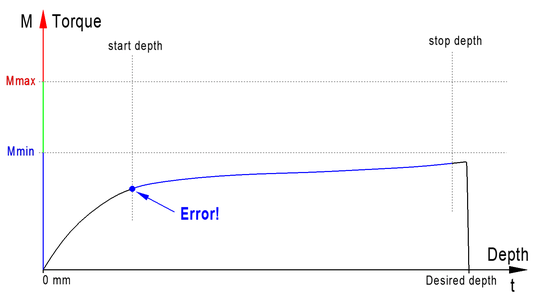

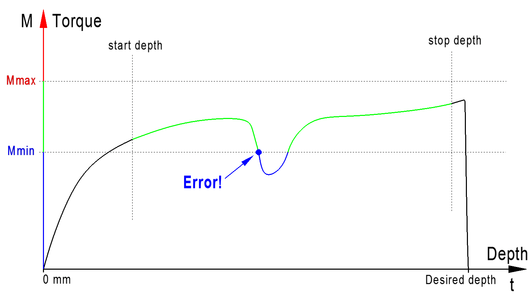

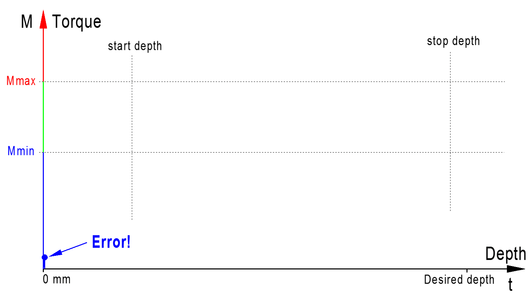

Examples: Process deviation and error during the machining.

Monitoring of the maximum torque is always active to protect the tool.

The minimum torque is optional adjustable.

Additional parameters are evaluated in combination with the torque, i.e.: Depth, time, feed orientation etc.

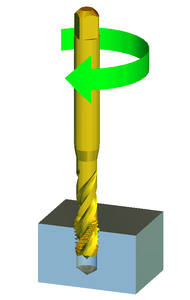

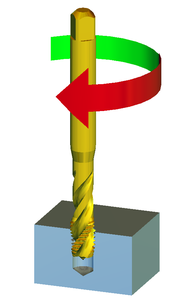

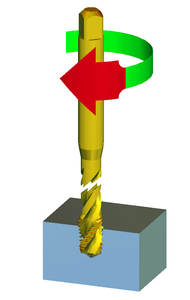

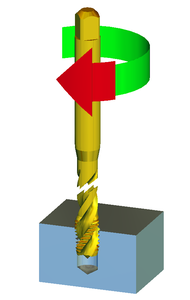

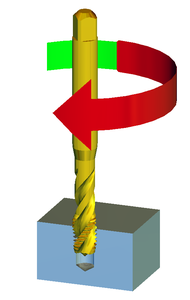

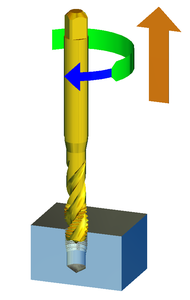

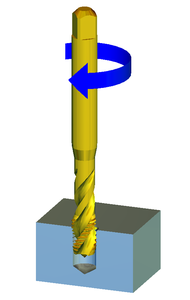

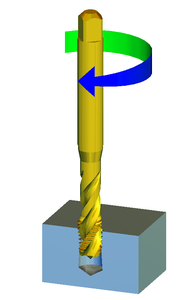

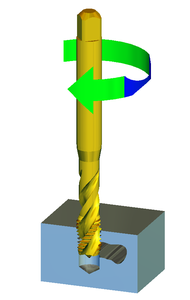

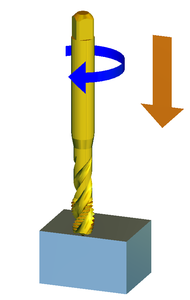

The torque is visualized as arrow around the tapping tool:

| green | → | correct torque |

| blue | → | torque too low |

| red | → | torque too high or error |

No Error

The thread complies with the

required quality

Tool wear

Detection of a worn tool

Prevention of tool breakage

due to too low drilling depth

Prevention of tool breakage

due to fatigue

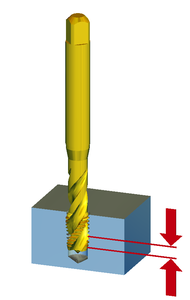

Drilling too small

Detection of a too small drilling

Detection of torn out threads

Drilling too large

Detection of a too large tap

drill diameter

Detection of a conical drilling

Detection of cavities

(air pockets and blow holes)

within castings

Detection of a missing borehole

Detection of a differing thread depth