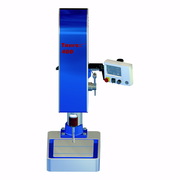

Taurox 400 M5 - M18

The Taurox 400 connects seamlessly to the next smalles model, the Taurox 300 and has with a maximum torque of 40Nm 25% more reserves. The quality monitoring system ensures reliable processing and early detection of quality issues. Effective tool breakage prevention for every specified thread size saves money and time. The monitored servo drive ensures great dynamics with very smooth running. The operating unit with a 4.3“ TFT display, push button and rotary knob, provides a clear and intuitive menu guidance.

For more information, please contact us directly.

- Languages: German / English / Spanish (more on request)

- Operation: menu-guided via rotary knob and button

- Display: 4.3“ color TFT–display with graphic quality evaluation

- Depth unit: mm / inch

- Torque monitoring with actual value display

- Independent of thread type and pitch

- Process programs: thread cutting, thread forming, Thread tapping to basic contact with depth tolerance, rethreading with lead monitoring, thread inserts, screw in, thread plug gauge

- Chip clearance programs

- Grade of quality: blowhole, array of torque, tolerance of depth, tool wear

- Start program: Start with start button, Start at workpiece zero point, Start at torque detection

(automatic zero point identification with rotating spindle)

All start programs are compatible with feed for spindle feed*. - Rotation: right and left rotation switchable

- Reversal program: variable speed 20% - 1000% (max. speed)

- Parameter database: 99 parameter data records

- Counter: Daily counter, Part counter, Quantity counter, OK / not OK adjustable with subsequent lock

- Lubrication program: Cooling lubricant and blow-out programs optimized for minimal quantity lubrication technology*

- Switching function for power outputs* for valves such as pneumatic part holder 24 V DC / 3.6 W

- Digital inputs / outputs* for automation with pre-assigned functions

*Options / Accessories

| Thread capacity thread cutting (AlMg4.5Mn / 3.3547) |

M5 – M18; blind hole 2.0 x D |

| Thread capacity thread cutting (X6CrNiMoTi17–12–2 / 1.4571 / V4A) |

M5 – M16; blind hole 1.5 x D |

| Torque range adjustable | 2.00 - 40.00 Nm |

| Speed range adjustable | 50 – 600 rpm max. 500 rpm from 25 Nm |

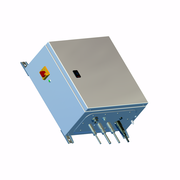

| Modular construction (3-parts) |

– spindle unit – operator and display unit – control unit |

| Operation | Menu driven |

| LCD Display | 4.3“ TFT–display, 65536 colors |

| Spindle / tool holder | quick change holder Size 2 |

| Outreach | 201 mm |

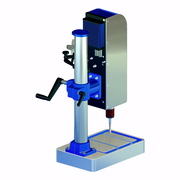

| Travel height adjustment Column Ø / length / swivel range |

0 – 425 mm with hand crank 70 mm / 730 mm / 60° |

| Machine pedestal (WxDxH) | 469 x 296 x 75 mm T-slots DIN 650-12 |

| Dimensions machine (WxDxH) | 484 / 469 / 1200 mm |

| Dimensions control unit (BxTxH) | 400 / 210 / 400 mm |

| Weight with control unit | 97 kg |

| Electric supply / Power input | 230 V~ / 1.1kW |

| Power input non-operated | < 40 W |

| Cable length between the modules | 3 m (others on request) |

| Spindle travel / thread depth | 90 / 80 mm |

| Depth accuracy | 0.1 mm |

| Entrance protection class | IP54 |

| Engineer standard | CE– / EMV–konform |

| Digital inputs* | 3 (24 V) |

| Digital outputs* | 10 (24 V / 3.6 W) short-circuit proof |

| Finish RAL / colour name |

RAL 7035 / light grey RAL 5005 / signal blue |

| Quality evaluations / Error messages |

Display with error message Evaluation and audible signal |

*Options / Accessories

- Quick change inserts size 1

- Quick change holder size 2

- Quick change inserts size 2

- Spindle feed system

- Height adjustment (column) with longer travel

- Minimum lubricant unit 2V with lubricant pulse and air pulse

- Minimum lubricant unit 3V with lubricant pulse, air pulse and air cleaning pulse

- Signalbar green, yellow and red for optical quality evaluation in the field of view of

processing - Signal light column green, yellow, red and horn for quality evaluation

- Additional push buttons selection for parameter data base

- Key switch with locking of the user interface

- External operating lock via input 24V DC

- Connection for external emergency stop and motor lock on control unit

- Automation connection via digital inputs and outputs

- Ethernet interface for control unit

- TauroView software for PC to visualize the required torque and optimize the processing parameters

- Customized machine software

- Custom Modbus for automation

- Customized cable lengths