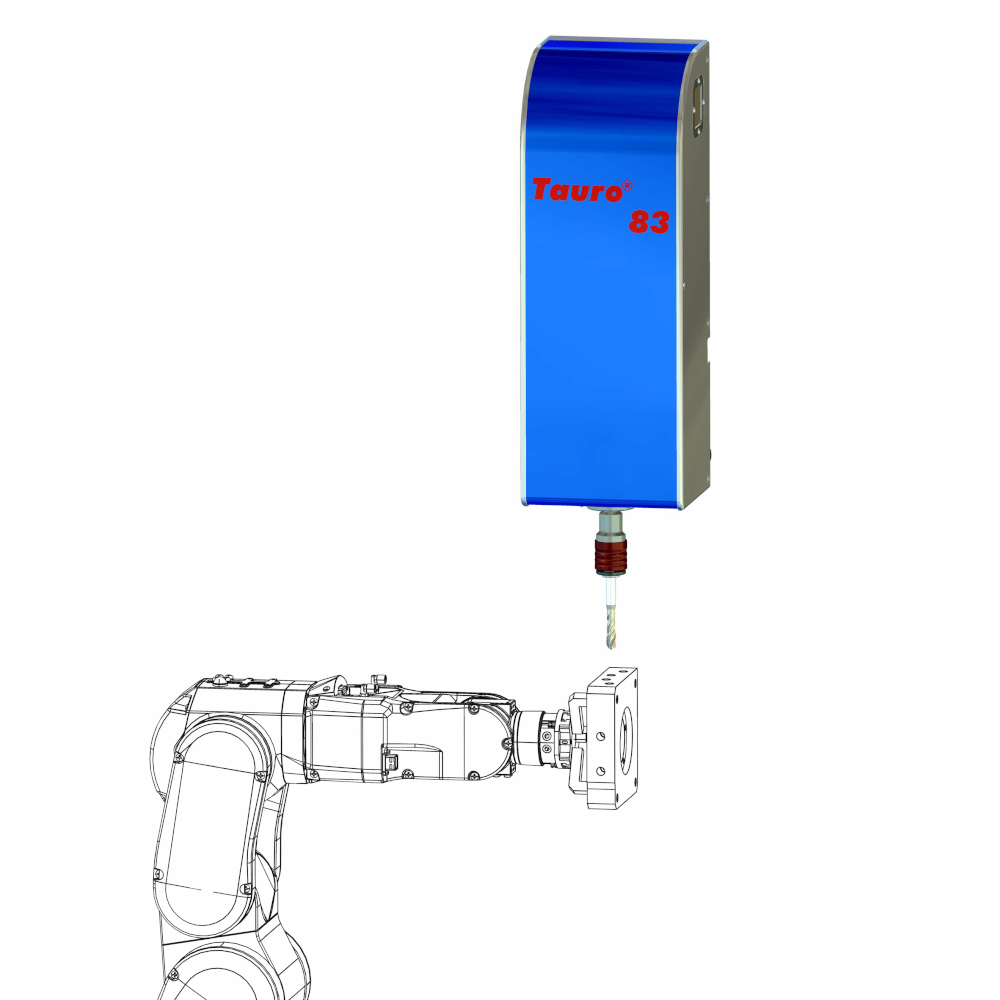

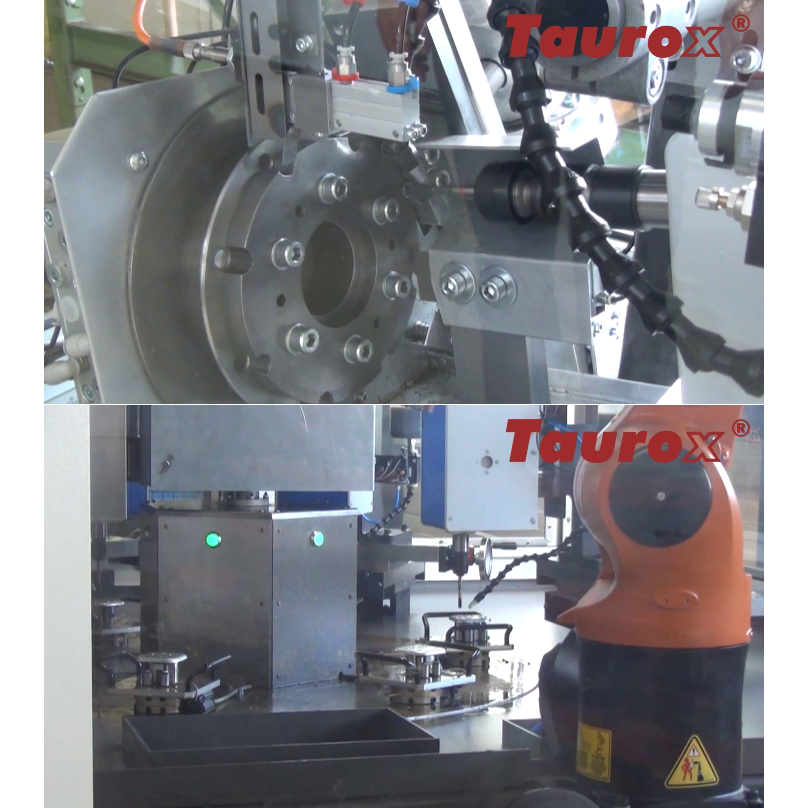

Thread Manufacturing in Automation

Taurox threading units for automated thread manufacturing stand out with seamless quality control, the marking of defective parts, and alerts for worn tools. They also deliver high production volumes thanks to rapid processing and optimized machining parameters. With a built-in PLC interface, these units integrate effortlessly into automation systems. We provide comprehensive support and consulting to help you incorporate our machines into your existing or planned automation setups. Additionally, we can facilitate complete automation solutions in collaboration with our trusted partners.

PLC interface

A PLC interface is located on the rear of the drive unit, which allows the tapping unit to be seamlessly integrated into an automation system. A machining process can be started via this interface, while the current status of the machine is queried at the same time. The interface also provides feedback on the quality of the last machining operation so that faulty parts can be sorted out automatically.

Modbus TCP

The Tauro thread tapping unit enables seamless communication with automation systems via the Ethernet interface using Modbus TCP. This allows operating states and parameters to be queried and settings to be made. Customer-specific extensions to the Modbus protocol are possible on request.